Tube labeling is critical for accurate sample identification in labs. Test tubes — a common form of laboratory glassware used to hold and mix substances — require clear, durable labels to prevent sample mix-ups. (See Wikipedia’s overview of test tubes for background.) This article covers automated and semi-automated labeling solutions that improve efficiency and reduce errors.

Key Takeaways

-

Automated tube labelers significantly improve lab efficiency by reducing labeling time and minimizing human error.

-

Versatile labeling machines like the GoDEX GTL-100 accommodate various tube sizes and ensure accurate, consistent label application.

-

Advanced features such as direct thermal printing and barcode integration enhance the precision and data management capabilities of labeling systems.

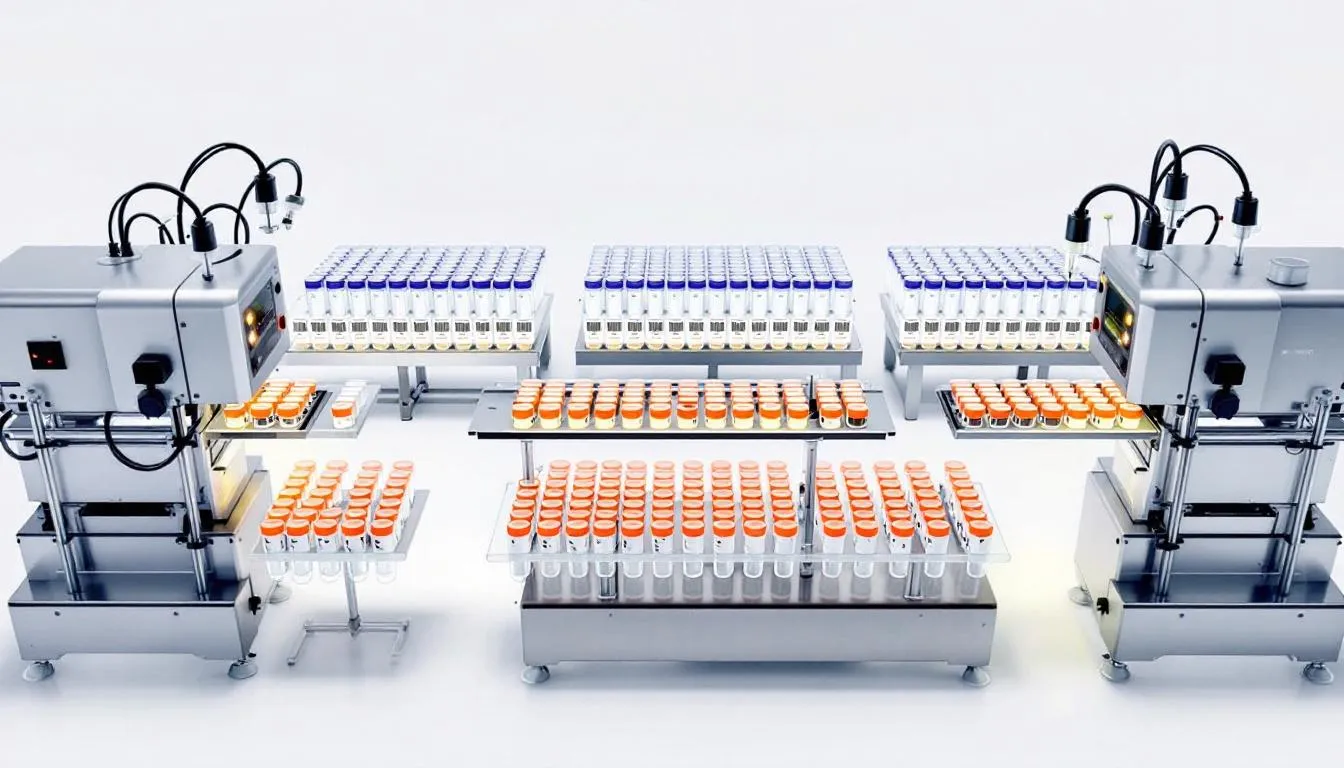

Automated Tube Labelers for Labs

Automated tube labelers are a game-changer for labs, designed to enhance accuracy and speed while minimizing the risk of labeling mistakes. These machines take the guesswork out of labeling, allowing lab personnel to focus on more critical tasks. The efficiency gained through automation translates to more samples processed in less time, directly impacting the productivity of lab operations.

Label applicators come in various forms, each tailored to specific needs. From the GoDEX GTL-100 Test Tube Labeler to semi-automated options like Primera’s AP-Series, there’s a solution for every lab. Each machine’s unique features and benefits will be detailed below.

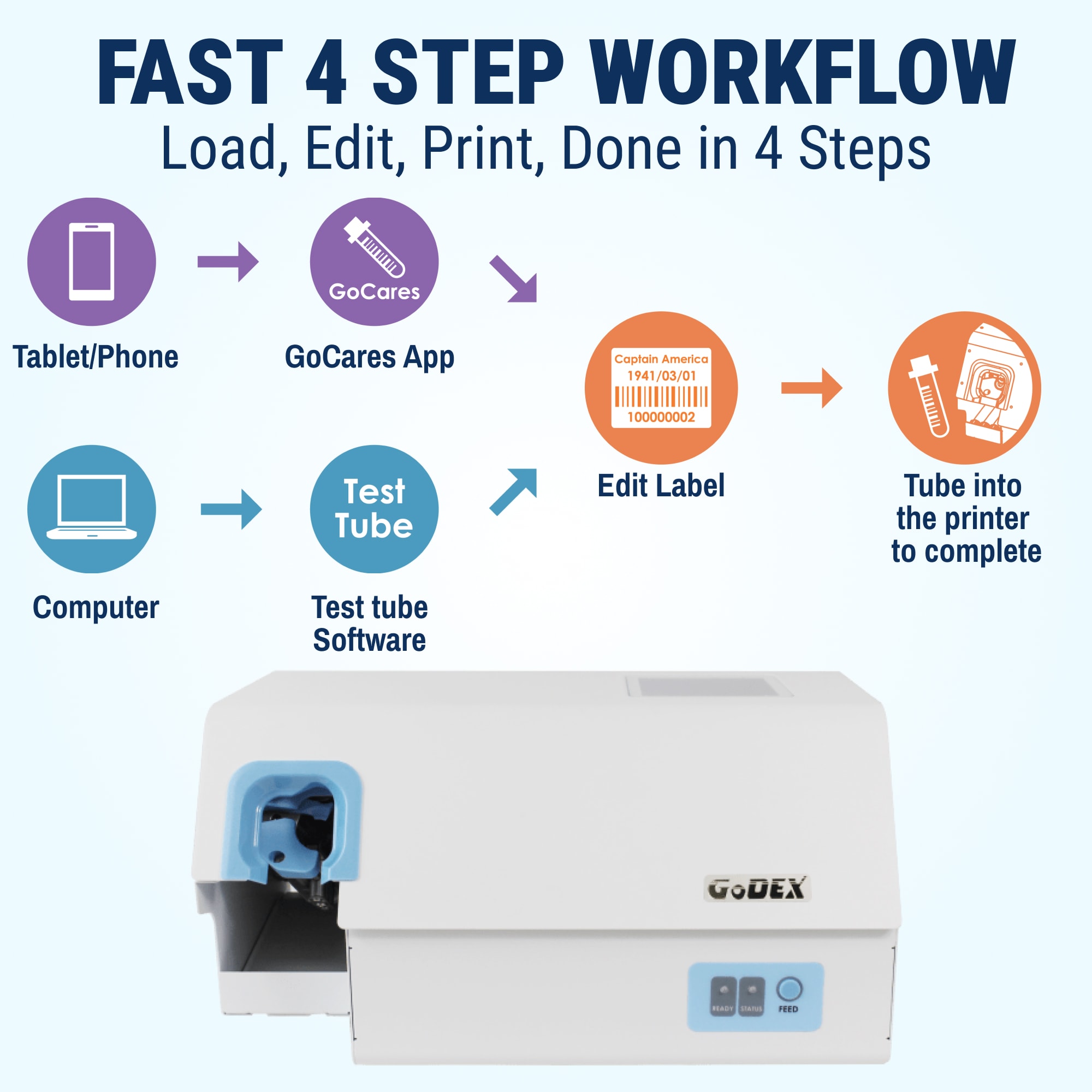

GoDEX GTL-100 Test Tube Labeler

The GoDEX GTL-100 is a versatile workhorse in the realm of automated tube labelers. Capable of labeling tubes ranging from 0.5 mL to 50 mL, it supports a wide variety of tube sizes, making it suitable for diverse laboratory applications. Labs handling various types of samples benefit from this flexibility, reducing the necessity for multiple labeling systems.

Designed to accommodate both glass and plastic test tubes with diameters between 13 to 16 mm and lengths of 75 to 100 mm, the GTL-100 ensures that labels are applied accurately and consistently. Maintaining this level of precision is vital for lab result integrity and compliance with industry standards.

Semi-Automated Laboratory Tube Labelers

Labs seeking a more cost-effective solution will find the semi-automated tube labelers like Primera’s AP-Series to be well-balanced. These label applicators are designed for ease of use and can handle a variety of labeling tasks, from cylindrical containers to jars and bottles. The versatility of these machines makes them an excellent choice for labs with diverse labeling needs, including a vial labeler.

One standout feature of the AP-Series is the integrated label liner rewinder, which keeps labels organized during operation, thereby improving overall efficiency. Additionally, semi-automated systems are often more budget-friendly, making them accessible for labs with tighter budgets.

Key Features of Tube Labeling Machines

Key features of tube labeling machines that can greatly enhance the efficiency and accuracy of lab operations include:

-

Minimal manual intervention, ensuring precise labeling without extensive training

-

Integration of automated solutions to enhance production speed

-

Streamlining lab operations by reducing reliance on human labor for repetitive tasks

A crucial aspect of these labelers is their ability to apply labels without misalignment, ensuring a consistent and professional appearance. Additionally, the ability to customize data fields allows labs to tailor labels to specific requirements, enhancing data management and accuracy.

Speed and Efficiency

Speed is a vital factor in lab operations, and automated labelers excel in this area. Key points include:

-

Automated labelers can apply labels in approximately 2 seconds.

-

Manual application can take up to 10 seconds per label.

-

This results in substantial time savings.

-

Rapid processing enables labelers to manage hundreds of tubes per hour.

-

This significantly cuts down the time researchers spend on manual labeling.

Automated labeling machines operate continuously without the need for breaks, further enhancing operational efficiency. Because these machines operate continuously, labeling tasks are completed faster than with manual or semi-automatic systems, freeing up lab personnel for more complex tasks.

Precision and Accuracy

Precision and accuracy are crucial in lab environments. Key points include:

-

Direct thermal printing at 203 dpi is key for maintaining high precision in labeling applications.

-

High-accuracy labeling machines can achieve a precision margin of only +/- 0.1mm.

-

This level of precision is crucial for compliance in regulated sectors.

These systems significantly reduce misidentifications by ensuring accurate and uniform label application. This level of precision guidance is vital to avoid misidentification, which can lead to serious consequences in laboratory settings.

Versatility in Tube Sizes

Versatility in handling various tube sizes is a hallmark of modern tube labeling machines. These machines are designed to accommodate different tube lengths and diameters, ensuring flexibility in labeling different products. Many machines can adjust to label tubes with diameters ranging from 10mm to 100mm, offering versatility for various product sizes.

Consider the tube sizes and volumes frequently used in your lab when choosing a labeler. Modern labelers can accommodate a wide range of tube diameters and lengths, providing the necessary flexibility for diverse packaging size needs.

Benefits of Using Automated Tube Labelers

The benefits of using automated tube labelers in lab environments are manifold:

-

They enhance efficiency by applying high-quality labels to various lab tubes, including cryovials and syringes.

-

Automated systems minimize manual labeling time.

-

They significantly speed up the labeling process in lab settings.

While the initial investment may seem high, automated labeling leads to long-term savings through reduced labor costs and increased efficiency. Automated systems eliminate common mistakes that occur during manual labeling, such as incorrect label placement, thereby enhancing overall lab efficiency.

Minimizing Human Error

One of the most significant benefits of automated tube labelers is their ability to minimize human error. These machines enhance efficiency and accuracy, significantly reducing human error in sample identification. Precision in labeling is crucial for avoiding misidentification, supported by technologies that maintain accuracy.

Technologies like direct thermal printing eliminate the need for ribbons and enhance reliability. Semi-automated tube labelers offer cost-effective solutions that streamline lab workflows while minimizing human error.

Time-Saving

Time-saving is another crucial benefit of automated tube labelers. These machines:

-

Significantly enhance lab efficiency by providing accurate and fast labeling solutions.

-

Streamline lab workflows, facilitating more efficient sample handling.

-

Increase throughput.

The GoDEX GTL-100 test tube labeler can apply labels in just 3 seconds, dramatically speeding up the labeling process. Automated labeling solutions streamline lab operations, boosting overall productivity and efficiency.

Improved Lab Workflow

Integrating automated tube labelers into lab workflows enhances efficiency by streamlining the labeling process, which minimizes delays and enhances productivity. Automated tube labelers significantly reduce human error during sample identification, ensuring that samples are accurately labeled and handled.

Integrating barcodes into automated tube labelers enhances sample tracking and management, further improving overall workflow efficiency. Automated labeling solutions save time by quickly applying labels, allowing for faster processing of samples compared to manual methods.

Advanced Labeling Technologies

Advanced labeling technologies play a crucial role in improving the efficiency and precision of tube labeling machines. Many of these machines utilize cutting-edge technologies to enhance their performance, ensuring that labels are applied accurately and consistently.

The next subsections will explore advanced technologies like direct thermal printing, barcode integration, and custom data fields, each enhancing the efficiency and accuracy of tube labeling.

Direct Thermal Printing

Direct thermal printing is transformative for tube labeling. It uses heat-sensitive materials to create labels, eliminating the need for additional ribbon supplies and simplifying the process. Direct thermal printers used in labeling can produce images with a resolution of up to 600 dpi, enhancing clarity and detail.

Printing 1D and 2D barcodes without ribbons adds another layer of convenience and efficiency. The sci print solo printer exemplifies these capabilities, making it an ideal choice for labs looking to streamline their labeling processes.

Barcode Integration

Barcode integration is a crucial feature in modern tube labeling machines, supporting both 1D and 2D barcodes to streamline data management and tracking in laboratory settings. This capability enhances the flexibility of data capture systems, making it easier to track and manage samples.

Supporting both 1D and 2D barcodes improves sample tracking, ensuring accurate labeling and easy traceability. This integration is essential for maintaining the integrity of lab results and improving overall workflow efficiency.

Custom Data Fields

Custom data fields in labeling systems provide labs with the flexibility to input specific information tailored to their unique requirements. These fields can include details such as sample type, collection date, or any other relevant lab-specific information, ensuring that essential data is readily available and easily accessible.

Customizing labeling systems with specific fields enhances lab efficiency and accuracy, improves data management and overall workflow.

Choosing the Right Tube Labeler

Selecting the right tube labeler involves considering factors to ensure it meets your lab’s specific needs and is compatible with your tube sizes and types. Many of these machines feature easy operation with user-friendly controls, minimizing the need for specialized training.

Operators often need to manually load pre roll tubes, which can lower initial investment costs compared to fully automated systems. This consideration is crucial for labs looking to balance functionality and cost-effectively.

Budget Considerations

Budget is a significant factor when choosing a tube labeler. The GoDEX GTL-100 test tube labeler is currently priced at $3,055.50, making it a competitive option in the market. Automated labeling systems minimize human error in sample identification, which can save costs associated with erroneous results and retesting.

Automated tube labelers enhance lab workflow efficiency, boosting productivity and reducing operational costs over time. Assessing the specific requirements of a lab ensures the selection of a tube labeler that balances functionality and cost, ultimately maximizing value.

Warranty and Support

Warranty and support are crucial considerations when choosing a tube labeler. A robust warranty ensures peace of mind and reliability in operations, reducing potential downtime. The GoDEX GTL-100 comes with a comprehensive 3-year warranty, covering parts and labor.

Customer support includes timely responses to technical inquiries and maintenance assistance, enhancing user experience. Investing in machines like the GTL-100, with solid warranty and support, promotes long-term efficiency and satisfaction.

Summary

Automated tube labelers represent a significant advancement in lab efficiency and accuracy. From the versatile GoDEX GTL-100 to cost-effective semi-automated solutions, these machines offer a range of benefits that can transform lab operations. Key features such as speed, precision, and the ability to handle various tube sizes ensure that labs can meet their specific needs effectively.

As labs continue to explore and integrate these advanced labeling technologies, the potential for improved workflow and reduced human error becomes increasingly apparent. Investing in the right tube labeler not only enhances productivity but also ensures the accuracy and reliability of lab results.

Frequently Asked Questions

How do you label a mailing tube?

To label a mailing tube effectively, include your company logo, product information, and clear shipping instructions. You can print the label directly on the tube or use a separate label affixed securely.

How many happy customers does McAuley Labels have?

McAuley Labels has over 100,000 happy customers.

What is the price of the GoDEX GTL-100 Test Tube Labeler?

The GoDEX GTL-100 Test Tube Labeler is currently priced at $3,055.50, down from its regular price of $3,435.00.

How quickly can the GoDEX GTL-100 apply labels to tubes?

The GoDEX GTL-100 can label and apply directly to tubes in just 3 seconds. This rapid labeling capability enhances efficiency in your operations.

What types of barcodes does the GoDEX GTL-100 support?

The GoDEX GTL-100 supports both 1D and 2D barcodes, along with custom data fields. This versatility allows for a wide range of applications. Combining with a 1D barcode reader allows you a quicker and easier approach to your workload.